Your Cart is Empty

Radium Fuel Hanger Surge Tank (FHST), 350Z/G35/G37/Q50/Q60, Fits Walbro F90000267/274/285 or DW440

$1,469.00

The Radium Engineering FHST (fuel hanger surge tank) is the ultimate solution for fuel starvation issues in the Nissan Z33/V35 chassis. Due to the saddlebag style OEM fuel tank and insufficient baffling, fuel starvation is common when the vehicle is driven aggressively, such as on a track. This results in unstable fuel pressure and possible engine damage from running too lean. A stand-alone surge tank is an excellent device for eliminating fuel starvation issues. But installing a stand-alone FST is difficult specifically in the 350Z due to the open-cabin design, and lack of a firewall between the driver and the rear of the vehicle. So Radium Engineering chose to create a fully functional fuel surge tank INSIDE the OEM tank.

The Radium FHST can be used with 1 or 2 aftermarket pumps and supplies 1:1 regulated fuel to the engine. No grinding, bending, or modification of the vehicle's sheet metal is required. Furthermore, the system is compatible with alternative fuels such as E85.

Features

-Drop-In Installation

-Permits 1 or 2 Surge Pumps

-Brushless Fuel Pump Compatibility

-Integrated 1:1 Adjustable Fuel Pressure Regulator

-Fuel Pressure Gauge

-Fuel Starvation Protection

-High Current Electrical Hardware

-Compatibility with Popular Fuel Pumps

-Anodised Aluminium Construction

-Gasoline, Methanol, and Ethanol Compliant

-Fuel Resistant Tubing and Wiring

-Stainless Steel Hardware

-New Anti-rotation Electrical Terminals

(See 'product info below for more!)

If you have a deadline to meet, please confirm that we have stock ready for dispatch to avoid disappointment!

FREE SHIPPING ON ORDERS OVER $1200!**

Product Info

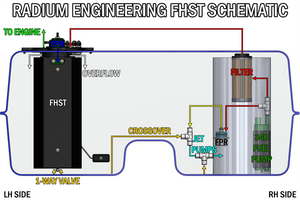

HOW THE FHST WORKS

The OEM fuel module contains the pump, fuel pressure regulator, filter and has 2 venturi jet pumps that supply fuel from both sides of the tank. However, the OEM fuel module still suffers from slosh, resulting in an interruption of the engine's fuel supply.

The Radium FHST is the best solution in preventing fuel starvation. It installs in the opposite side of the fuel tank from the OEM fuel module and works together to keep fuel-delivery consistent in all conditions. The OEM fuel module receives an upgraded fuel pump which is used to send fuel to the Radium FHST, keeping the collector box filled. The OEM venturi jet pumps will still function as designed, scavenging fuel from the bottom of the tank. The FHST pump(s) are used to supply fuel to the engine through an integrated fuel pressure regulator. As described below, the FHST pump(s) are supplied with fuel from 3 different sources: the pump in the OEM fuel module, the integrated fuel pressure regulator return, and 355LPH one-way fill valves on the bottom of the collector box that allows fuel in, but not out.

NOTES:

1. The OEM venturi system must be used with the Radium FHST.

2. The OEM fuel module must be upgraded to a pump with at least 340LPH (@ 40psi) rated flow in order for the venturi system to work correctly.

3. Do NOT modify the OEM FPR or OEM venturi jet pump.

4. Starvation will NOT prematurely occur, but the fuel level gauge will not read accurately.

INTEGRATED FUEL PRESSURE REGULATOR

Because the Nissan fuel system is "returnless", forced induction tuning can be problematic when a 1:1 fuel to boost pressure ratio is not possible. Like the OEM setup, a fuel pressure regulator (FPR) is integrated into the Radium FHST. The difference is the regulator is externally mounted with an adjustment screw and a vacuum port. If an intake manifold vacuum hose is connected, the FHST's built-in fuel pressure regulator will operate at a 1:1 ratio, permitting fuel pressure to proportionally increase with manifold (boost) pressure. Conversely, the vacuum port can remain open to atmosphere and pressure will remain constant (like OEM).

The returning low pressure fuel from the FPR is sent back into the FST collector box, keeping it full. Refer to the installation instructions link above for more details.

NOTE: The Radium integrated regulator should be the only FPR in the fuel system.

RA-series regulators feature a 360 degree swivelling vacuum reference port that is double O-ring sealed. This is the first in the industry. It permits the installer to quickly point the vacuum fitting in any direction with no tools required.

There are 4 interchangeable 10-32 threaded vacuum port fittings provided to cover all scenarios.

1. Barbed Fitting: A black zinc-plated 3/16" (5mm) barb machined from high strength steel that is compatible with the following vacuum hoses: 5/32" (4mm), 3/16" (5mm), and 7/32" (6mm).

2. 3AN Male Fitting: A black zinc-plated adapter machined from high strength steel that is compatible with 3AN hose ends.

3. Push-To-Connect: A nickel-plated brass fitting with Buna-N O-rings that is compatible with hard plastic 1/4" OD tubing.

4. Vacuum Plug: A black oxide stainless steel screw that is used to maintain a constant (non-dynamic) fuel pressure. Beginning in the mid 1990s, vehicle manufacturers started transitioning to returnless fuel systems to lower EVAP emissions. To keep temperatures lower, these regulators are mounted inside the tank and do NOT have the ability to be vacuum referenced. This plug would be required in this scenario.

NOTE: When installing the vacuum fitting, it is recommended to use a wicking medium-strength threadlocker.

PLUMBING

To clear the OEM LH cover plate, the 8AN ORB threaded feed port and 6AN ORB threaded inlet port feature pre-installed low profile 6AN male fittings. The 6AN ORB threaded "FPR" port is plugged and is only to be used if 20-0806 is purchased.

While the pump "OUT" fitting can always be changed (if necessary), the FHST "IN" fitting cannot be changed. The "IN" fitting incorporates a unique component that is required for the venturi system to work properly.

Two 6AN fuel hoses are provided to mate each side of the fuel tank units together. The system provides all necessary adapter fittings to reconnect the OEM fuel feed line. For high flow applications, it is recommended to run a large 8AN fuel feed line from the FHST to the fuel rail(s). Part number 20-1000-0808 8AN adapter fittings can be purchased separately and installed into the FHST "OUT" port. A custom 8AN fuel line will also need to be configured and assembled by the installer.

Sock filters are used on all fuel pump inlets. And because the FHST does NOT eliminate the low micron OEM post pump filter, a downstream aftermarket filter is recommended, but not required.

ELECTRICAL

The custom designed anti-rotation stainless electrical studs easily handle the high current demand that compact multi-pin bulkhead connectors lack. These serviceable connections are hermetically sealed and impervious to all standard and exotic fuels. Non-conductive anodised aluminium acorn nuts are provided to prevent any accidental short-circuiting. Electrical hardware is included for the fuel pump(s) and OEM level sender. Furthermore, the in-tank wiring is insulated with high quality chemically resistant ETFE.

This kit includes 1 relay, 1 fuse, and all associated wiring and hardware to install 1 surge tank pump.

PUMP COMPATIBILITY

Brushed and brushless fuel pump options are available for the FHST. The system is suited, but not limited, to the following fuel pumps:

20-1830

Walbro GSS342

AEM 50-1200 E85

20-1832

Walbro F90000267

Walbro F90000274

Walbro F90000285

Deatschwerks DW440 (brushless)

INCLUDED

The comprehensive kit includes all parts necessary to complete the installation including a pressure gauge, external fuel hose, fittings, electrical fuse, relay etc. The user must purchase fuel pumps separately.

Shipping & Returns

Free Shipping does not apply to some heavy items, for example: Wisefab & BC Racing are included for free shipping, NPC and some PWR are not included.

Shipping times may vary depending on your location, however the majority of packages are received within 3-5 business days of dispatch!

We dispatch 5 days a week, and aim to process all orders within 24hrs*

On weekends and public holidays, orders will be processed next business day.

*order processing may be delayed during sale events or holiday periods.

Payment Methods

We accept all major payment methods including Visa, Mastercard, AMEX & Paypal.

You may also like

looking for something specific?

Contact Us Today!

We can help with any project you are working on!

Need a specific part?

Just let us know what you are looking for and we will get back to you within 2-3 business days!